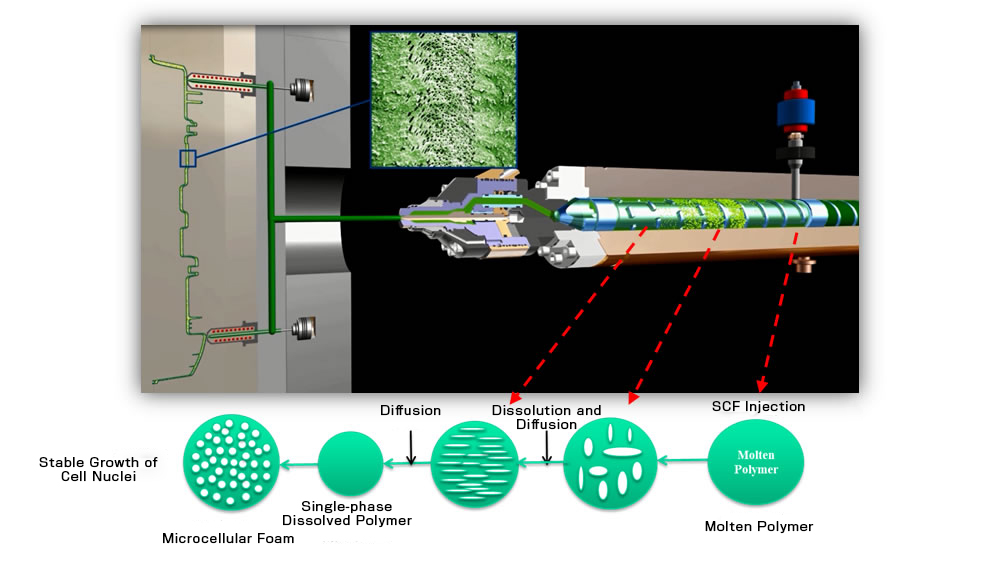

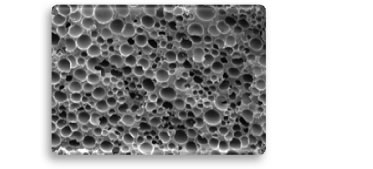

MuCell® microcellular foaming molding is a process that introduces supercritical nitrogen or carbon dioxide into molten resin to form fine cells with an average diameter of less than 100 micrometers within the molded product.

This technique leverages the characteristics of physical foaming to produce lightweight and highly precise molded products, which are used in various fields and applications such as automotive, packaging, and home appliances.

Features of the MuCell Process

- ■ Reduction of molten viscosity due to gas addition

- ■ Low-pressure, low-distortion molding utilizing foaming

Expected Benefits

- ・Improved product quality: Enhanced dimensional accuracy (reduction of warping and sink marks)

- ・Weight reduction: Material savings and product weight reduction

- ・Reduction in mold clamping force

- ・Shortened cycle time (elimination of holding pressure time)

Product Examples

Margarine Container Material:PP

Benefits

- ・6% reduction in material and weight

- ・40% reduction in mold clamping force

- ・15% reduction in injection pressure, enabling thin-wall in-mold labeling due to reduced cavity pressure

Airbag Cover Material:PP/EPDM

Benefits

- ・Uniform shrinkage for varying wall thicknesses, improved dimensional stability

- ・Improved hinge properties at -30℃

- ・9% reduction in material and weight

- ・Painted product

MuCell Trial Machine

Electric Servo Injection Molding Machine

Screw Diameter: 50 mm

Mold Clamping Force: 180 tons

To use MuCell® technology, a purchase agreement for the SCF supply equipment (including patent licenses) is required.

For more details, please contact Trexel Japan Co., Ltd. (1-6-4 Osaki, Shinagawa-ku, Tokyo, Tel: 03-6417-0072).